Could a robust PSM program have prevented the Deepwater Horizon disaster?

From tragedy to transformation: Rethinking process safety in high-risk industries

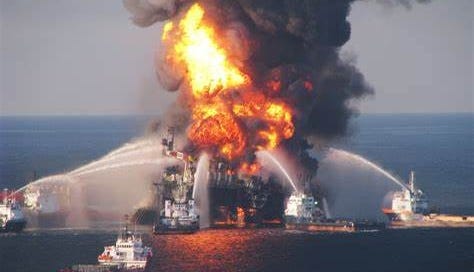

The Deepwater Horizon disaster of 2010 was a catastrophic event that exposed multiple safety failures and highlighted the critical importance of robust safety management systems in high-risk industries. On April 20, 2010, an explosion on the Deepwater Horizon rig, located 41 miles off the Louisiana coast, killed 11 workers, injured 17 others, and triggered the largest oil spill in U.S. waters--an estimated 4.9 million barrels of oil released into the Gulf of Mexico over 87 days. This incident serves as a stark reminder of the consequences of inadequate risk management and safety practices, with environmental, economic, and human costs still resonating years later.

Note: This article does not discuss the entirety of the incident but focuses on key safety failures and lessons learned.

Key Safety Failures

Inadequate risk assessment and management

BP and its contractors, including Transocean and Halliburton, failed to properly assess and mitigate major accident risks associated with the Deepwater Horizon rig and the Macondo well. The U.S. Chemical Safety Board (CSB) investigation found no evidence that BP conducted formal risk assessments of critical operational decisions in the days leading up to the blowout (AuditComply: The Story of Risk Management Failure - Deepwater Horizon). This lack of foresight extended to ignoring warning signs, such as abnormal pressure readings, which were misinterpreted or dismissed hours before the explosion.

Equipment failures and poor maintenance

Multiple equipment failures contributed to the disaster:

The blowout preventer (BOP), a critical safety device meant to seal the well in emergencies, failed due to faulty wiring, a dead battery, and a bent pipe, rendering it ineffective when the well surged (WorkBoat: Deepwater Horizon blowout preventer failed).

Poor maintenance of electrical equipment likely ignited the explosion, with reports indicating that gas detectors on the rig were not functioning properly (Wikipedia: Deepwater Horizon explosion).

Gas alarms and automatic shutdown systems were bypassed or disabled, preventing early detection and response to the gas buildup that led to the explosion (New Scientist: The eight failures that caused the Gulf oil spill).

Investigations later revealed that some of these issues were known prior to the incident but were not addressed due to cost-cutting measures and time pressures.

Flawed well design and testing

BP and Halliburton did not properly design and cement the Macondo well to control formation pressures and fluids. The cement mixture used was unstable and failed to seal the well effectively, allowing hydrocarbons to migrate upward. Additionally, BP failed to conduct an accurate pressure integrity test, misinterpreting results that indicated potential leaks (The Chemical Engineer: Deepwater Horizon: As it Happened). A critical decision to use fewer centralizers than recommended exacerbated the risk, channeling cement improperly and contributing to the eventual blowout.

Insufficient training and emergency preparedness

Personnel on the rig lacked adequate training on when and how to shut down engines or disconnect the rig from the well in an emergency. Transocean’s protocols did not sufficiently address high-flow emergency scenarios, leaving workers unprepared to manage the rapid escalation of events (SEC: Deepwater Horizon Accident Investigation Report). Moreover, there was a lack of clear communication and decision-making authority during the crisis, with some workers hesitating to activate emergency systems due to uncertainty or fear of repercussions.

Systemic issues

The disaster exposed deep-rooted systemic failures in BP’s safety culture and management systems:

Lower Standards for Contracted Rigs: BP applied less stringent safety standards to contracted rigs like the Deepwater Horizon compared to its own facilities, creating a disparity in safety oversight.

Production Over Safety: A culture prioritizing production over safety pervaded operations, often described as “running it until it breaks.” This mindset was evident in BP’s history of incidents, including the 2005 Texas City refinery explosion, which killed 15 workers and injured 180 (Forbes: BP Deepwater Horizon Arraignments: A Culture That "Forgot to be Afraid").

Inadequate Safety Management Systems: BP’s Safety Management System failed to enforce proper risk assessment, maintenance, and adherence to process safety standards, allowing preventable risks to accumulate over time (Chemistry World: BP’s misdirected safety focus blamed for Deepwater debacle).

These systemic issues were not isolated but part of a broader pattern of cost-cutting and risk-taking that investigations traced back years before the disaster (Slate: Blame BP for Deepwater Horizon).

Here’s the role of Process Safety Management (PSM)

Implementing a robust Process Safety Management (PSM) program, even when not required by regulations, could have potentially prevented or mitigated the Deepwater Horizon disaster. PSM, a framework developed to manage hazards in high-risk industries, includes several elements that directly address the failures observed:

Process Hazard Analysis (PHA)

A thorough PHA would have identified risks associated with the well design and cementing process, such as the potential for gas migration or cement failure. By mapping out these hazards, BP could have developed better mitigation strategies, possibly avoiding the conditions that led to the blowout.

Mechanical Integrity

A PSM program mandates regular inspections and maintenance of critical equipment like the BOP. Had this been in place, issues such as the dead battery or bent pipe might have been detected and rectified before the incident (WorkBoat: Deepwater Horizon blowout preventer failed).

Management of Change (MOC)

A formal MOC process would have ensured that alterations to the well design—like the decision to use fewer centralizers or modify cement formulations—were thoroughly evaluated for safety impacts. Without this, last-minute changes went unscrutinized, introducing unforeseen risks (ScienceDirect: Evacuation, escape, and rescue experiences).

Contractor Management

PSM requirements for contractor management could have improved coordination between BP, Transocean, and Halliburton, ensuring all parties adhered to unified safety standards. The lack of alignment contributed to miscommunications and differing priorities, exacerbating risks (Guardian: Deepwater oil spill a 'classic failure' of BP management).

Incident Investigation

A PSM-driven approach to incident investigation would have ensured that previous near-misses and smaller incidents on the rig—or similar operations—were thoroughly analyzed. This could have revealed systemic issues, such as recurring BOP maintenance problems or training gaps, before they culminated in a catastrophe (Nature.org: Lessons Learned from the Deepwater Horizon Recovery).

Lessons learned and path forward

The Deepwater Horizon disaster underscores the importance of applying PSM principles to all high-risk operations, even when not explicitly required by regulations. It also prompted significant regulatory and industry changes, including the strengthening of offshore drilling oversight by the U.S. Bureau of Safety and Environmental Enforcement (BSEE) and the development of new safety standards like the Safety and Environmental Management Systems (SEMS) rule.

This comprehensive approach to safety management can help companiesachieve several critical outcomes:

Enhance Safety Culture Across the Organization: Fostering a culture where safety outweighs production pressures is essential. This includes empowering workers to report hazards without fear of reprisal and ensuring leadership prioritizes safety metrics over profit margins.

Systematically Identify and Manage Process Hazards: Using tools like PHA and risk assessments can proactively identify potential failures, allowing for preventive measures rather than reactive fixes.

Improve Emergency Preparedness and Response: Regular drills, clear protocols, and well-trained personnel can make the difference between containment and catastrophe. Post-incident analyses stressed the need for better evacuation and rescue training, as some workers struggled to escape safely (ScienceDirect: Evacuation, escape, and rescue experiences).

Better Coordinate Between Operators and Contractors: Standardizing safety expectations across all parties involved in operations can reduce miscommunication and ensure accountability.

Continuously Improve Safety Systems and Procedures: Learning from incidents—both large and small—through rigorous investigations and feedback loops can drive ongoing improvements.

As of March 2025, the oil and gas industry continues to push boundaries with deeper drilling and operations in more challenging environments, such as the Arctic or ultra-deep waters. These advancements make it even more critical to prioritize safety and risk management. Implementing rigorous safety management systems like PSM, even when not regulated, alongside regular testing and maintenance of critical equipment, remains essential. Fostering a strong safety culture—where near-misses are reported, lessons are learned, and safety innovations are embraced—can prevent future disasters (The Chemical Engineer: After the spill: safety standards and metrics).

The Deepwater Horizon incident also had lasting environmental and economic impacts. The spill affected over 1,300 miles of Gulf Coast shoreline, devastated marine life (with NOAA estimating millions of fish and other organisms killed), and caused billions in economic losses for fishing and tourism industries (NOAA Fisheries: Deepwater Horizon 10 Years Later: 10 Questions). Cleanup efforts involved over 47,000 responders at their peak, and BP has paid over $65 billion in fines, settlements, and restoration costs as of recent reports.

There’s no shortcuts to safe operations

The Deepwater Horizon disaster remains a powerful reminder that there are no shortcuts to safety in high-risk industries. It exposed vulnerabilities that were not just technical but deeply cultural, revealing how complacency and cost-cutting can lead to unthinkable consequences. By learning from this tragedy—implementing comprehensive safety management practices, embracing PSM principles, and fostering a culture of vigilance—we can work toward preventing similar catastrophes in the future. As the industry evolves, the lessons of 2010 must continue to guide us, ensuring that safety remains the foundation of every operation, no matter how complex or ambitious.

Disclaimer: this is not legal advice and shall not be construed as such.